Warehouses represent the heart of supply chains, manufacturing, and logistics industries. Expansive facilities and high ceilings make it very challenging to offer sufficient illumination. High Bay LED Lights are revolutionizing this whole process. Today, they form the gold standard for lighting up warehouses. Not only do these lights enhance the visibility, but they also improve operational efficiency to a great extent. Let's discuss in this article the revolution being brought about by High Bay lights for warehousing and find out how they can be applied in real life.

Challenges of Traditional Warehouse Lighting

Warehouses used to rely on the illumination provided by fluorescent, halogen, or high-intensity discharge (HID) lamps for many years. While those were suitable options for their times, they are plagued with drawbacks. The big drawbacks were a high energy requirement, high maintenance needs, and inconsistent illumination.

Additionally, most of these older lighting systems do not deliver brightness consistency in the same manner, modern warehouses operate many that run all day long.

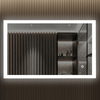

All these problems are a thing of the past with the introduction of High Bay LED Lights. Designed specifically for ceilings that are 20 to 45 feet high, they offer uniform, bright illumination and overcome the inefficiencies of older lighting systems.

Key Benefits of High Bay LED Lights in Warehouses

-

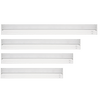

Energy Efficiency: These LED lights are famous for their energy-saving capabilities. LEDs consume less power compared to traditional HID or fluorescent lighting and offer the same, if not better, brightness. For example, a high bay light with 30,000 lumens can illuminate a large area effectively, reducing electricity bills.

-

Brightness and Color Temperature: Warehouses need constant lighting to ensure safety and productivity. High Bays, especially those offering 5000K color temperature, simulate daylight, making tasks like inventory management and quality checks easier. The clarity provided by these lights reduces eye strain and minimizes errors during work.

-

Long Life and Light Durability: The long life of high bay LED lights, sometimes lasting up to 50,000 hours or more, serves a fine purpose in warehouses where changing bulbs at high ceilings costs and time-consuming to change. Products like LED High Bay lights 200W, thus, are designed for industrial sites to provide sturdiness due to wear and tear.

-

Modern Features for Modern Requirements: Most warehouses use High Bay lights that have motion sensors, and their brightness automatically changes according to the activity levels. This helps reduce waste energy but also increases security since it only gives light when and where it is required.

-

An eco-friendly lighting option: In the present world where going green is everything, these warehouse lighting shine out as environmentally friendly. This is because compared to the general lights, LED lights do not contain mercury materials making their disposal easy and safe, hence sustainable.

Practical Implementations of High Bay Lights for Warehouse Lighting

1. Maximum Storage and Replenishment

Warehouses with tall shelves and densely packed storage rooms are often characterized by dark areas that obscure visibility. Industrial High Bay LED lights will ensure uniform lighting to allow employees to easily identify and access what they need. This is especially crucial in facilities dealing with perishable or time-sensitive products, such as pharmaceuticals.

2. Improved Safety Standards

Safety first when it comes to warehouse operations. Dull lights may cause mishaps, more so in those sections with forklifts, conveyors, and other heavy machinery. The high bay 5000K brightness LED improves visibility, ensuring less chance of injury at work. Other options are motion sensors that can specifically light up on areas with human movement, improving safety.

3. Simplify Inspection Processes

Quality control and inspection requires very high accuracy that is possible only under stable bright lighting. High Bay LED lights 30,000 lumens are quite ideal for detecting flaws in manufactured goods or analyzing the stock as well.

4. Assisting Automated Systems

Most modern warehouses have automation, from robotic pickers to conveyor systems. These systems actually require well-lit environments to operate well. Best High Bay LED produces a bright and flicker-free illumination that facilitates flawless operations of automatic systems, therefore enhancing total productivity.

5. Energy Savings in Cold Storage Warehouses

Cold storage facilities are perhaps the most energy-intensive spaces. The heat emitted by traditional lighting adds to cooling costs. High Bay LEDs generate minimal heat while delivering superior brightness, making them ideal for refrigerated environments.

Why are warehouses transitioning to High Bay LED Lights?

The shift from traditional lighting to warehouse lighting is no longer a fad but necessity, as today's industries need it. Because warehouses are fast becoming the modern hub for growth in e-commerce and advanced logistics, the demand for efficient, reliable, and innovative lighting solutions has never been so high.

Many warehouse managers who upgrade to High Bay LED lights 30,000 lumens or LED High Bay lights 200W often report large-scale energy savings and lower maintenance. Additionally, embracing smart technologies like motion sensors contributes to the overarching industry objectives of automation and efficiency.

Selecting the Best High Bay Lights for Your Warehouse

When choosing High Bay LED lights, one must put into consideration, among other elements, lumen output, color temperature, watts, and extras such as sensor-based motion functionality. Here's how to navigate the selection:

-

Consider Clearance Height and Workspace: The tall ceiling warehouses get high lumen output, probably 30 000 lumen models.

-

Value Energy Efficiency: High efficacy in LEDs will optimize energy efficiency savings.

- Consider Advanced Features: Motion sensors and dimmable options can enhance both functionality and efficiency.

- Check Color Temperature: For warehouses, a 5000K light provides the bright, white illumination necessary for clear visibility.

Future Trends in Warehouse Lighting

The future of lighting in warehouses is definitely LED-based with further moves toward the integration of smart technologies. IoT-enabled lighting systems, for example, enable the monitoring and control in real time. The vaults can now use their lighting to meet specific operational needs.

Increased sustainable practices are also stimulating the urgent development of even more energy-efficient LED models. Solar-powered LEDs and recyclable components are soon expected to become normal in industrial settings.

Wrap Up!

The change High Bay LED Lights bring to a warehouse is nothing less than revolutionary. From enhanced visibility and safety to energy efficiency and sustainability, they are an integral upgrade for warehouses in the modern world. Be it Industrial High Bay LED lights or models featuring smart features like motion sensors, the benefits are undeniable. At LEDMyPlace, we have a variety of High Bay LED lighting solutions designed to fit the specific needs of warehouses. Ready to change the game with your warehouse lighting? Browse our collection or book a video consultation with our experts today. Let's help you find the perfect lighting solution to illuminate your space and uplift your operations.