Introduction

Warehouses are the backbone of many businesses, serving as storage and distribution centers for a wide range of products. Properly organizing and managing a warehouse is crucial for smooth operations and increased productivity. One effective method for optimizing your warehouse is color coding. In this blog post, we'll explore how to color code a warehouse to improve efficiency and streamline your operations.

Why Color Code Your Warehouse?

Color coding is a visual management technique that simplifies processes, reduces errors, and enhances overall efficiency. It provides a quick and easy way for warehouse staff to identify and locate items, making it an invaluable tool in the quest for improved productivity. Here's how to get started:

-

Assess Your Inventory

Before diving into color coding, take the time to assess your inventory. Categorize your products based on factors such as size, shape, weight, and frequency of access. Create a list of product categories or groups that make sense for your specific warehouse.

-

Choose a Color Scheme

Once you have your product categories defined, select a color scheme for your warehouse. Keep in mind that color coding should be intuitive and easy to remember. You can use different colors for different categories or use shades of the same color for subcategories.

For instance:

- Red for high-priority items

- Blue for electronics

- Green for perishable goods

- Yellow for hazardous materials

- Orange for office supplies

-

Create a Color Coding Key

Develop a color coding key or legend that associates each color with a specific product category or type. Display this key prominently in your warehouse and provide copies to all staff members. Clear and consistent communication is essential for the success of your color coding system.

-

Labeling and Signage

Invest in high-quality labels and signage to implement your color coding system effectively. Label each storage location, shelf, or bin with the corresponding color and category label. Make sure the labels are durable and easy to read from a distance. Using color-coded floor tape or paint to mark aisles can also help guide employees.

-

Train Your Team

Training is critical to ensure that your staff understands the color coding system and uses it correctly. Conduct workshops or training sessions to familiarize your employees with the system and emphasize its importance in streamlining warehouse operations.

-

Regular Audits and Maintenance

To maintain the efficiency of your color coding system, schedule regular audits and inspections. Ensure that labels and signage remain intact, and update them as needed. As your inventory changes, adapt your color coding system accordingly.

Benefits of Color Coding

Implementing a color coding system in your warehouse can yield several benefits:

-

Reduced Errors: By simplifying product identification, color coding helps reduce picking and shipping errors.

-

Faster Retrieval: Warehouse staff can locate items more quickly, resulting in faster order fulfillment and reduced lead times.

-

Enhanced Safety: Color coding can help designate hazardous areas or materials, improving safety and compliance.

-

Improved Organization: A well-organized warehouse enhances overall productivity and reduces downtime.

-

Streamlined Training: New employees can quickly learn and adapt to the system, reducing onboarding time and costs.

Warehouse Lighting

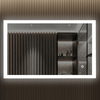

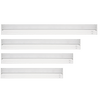

Proper lighting is a critical but often overlooked factor when implementing a color coding system in your warehouse. Adequate illumination is essential to ensure that employees can easily see and distinguish the color-coded labels, signs, and markings. Here's how to address lighting in your color coding strategy:

-

Uniform Lighting: Ensure that lighting throughout your warehouse is uniform, minimizing shadows and dark spots. This consistency will help staff accurately identify colors and labels, even in remote corners.

-

LED Lighting: Consider upgrading to energy-efficient LED lighting solutions. LEDs provide bright and consistent illumination, reduce energy costs, and require less maintenance compared to traditional lighting sources.

-

Lighting Controls: Implement lighting controls, such as motion sensors and timers, to save energy when specific areas of your warehouse are not in use. This not only reduces operating costs but also contributes to sustainability efforts.

-

Emergency Lighting: Install emergency lighting to maintain visibility during power outages or emergencies. This ensures that your color coding system remains functional even in adverse conditions.

-

Regular Maintenance: Routinely inspect and maintain your warehouse lighting system to replace burnt-out bulbs, clean fixtures, and address any issues promptly. Proper maintenance ensures that your color coding system remains visible and effective.

-

Natural Light: Whenever possible, leverage natural light sources to complement your artificial lighting. Skylights or large windows can reduce your dependence on artificial lighting during daylight hours.

Remember that proper warehouse lighting not only enhances the effectiveness of your color coding system but also contributes to overall safety and the well-being of your warehouse staff. It's an essential element to consider as you work to maximize productivity and efficiency in your warehouse.

Conclusion

Color coding is a simple yet powerful tool for optimizing warehouse operations. By categorizing your inventory, selecting a clear color scheme, and providing training and maintenance, you can harness the benefits of this visual management technique. A well-implemented color coding system can significantly increase efficiency, reduce errors, and contribute to the overall success of your warehouse operations. So, start color coding your warehouse today and watch your productivity soar.