Shadow lines can ruin the look of a freezer display. The products look uneven. Some sections look dark. Some areas look too bright. This is not a product problem. It is usually a lighting problem.

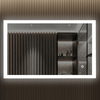

The good news is simple. You can fix it with better planning and placement. When you use cooler freezer LED lights correctly, the freezer looks cleaner and brighter. Also, good glass door freezer lighting helps customers see products clearly. This guide will show you what causes the shadow lines and how to stop them step by step.

Quick goals of this guide

-

Remove shadow bands and dark stripes

-

Improve visibility from top to bottom

-

Get clean, even light inside the door area

-

Create a professional display using commercial-grade lighting

Why Shadow Lines Happen in Glass-Door Cooler & Freezer Lighting

Light angle mismatch creates uneven illumination

First, shadows appear when light hits shelves and products at the wrong angle. If the LED strip points straight down, it leaves side areas darker. If it points too far back, the door-side becomes dim. So the light must face the product zone, not the back wall.

Obstructions inside the freezer block light flow

Second, objects inside the freezer block the beam. Product boxes, metal shelf edges, and door frames all create barriers. As a result, the light becomes broken into bright and dark sections. That is why smart LED cooler lights placement matters so much.

Narrow beam LEDs cause dark vertical bands

Some LED fixtures use narrow optics. This creates a tight, harsh beam. So you see bright lines and dark lines like stripes. This is one of the biggest causes of shadow lines in freezer lighting, especially in tall glass-door freezers.

Common Cooler Light Placement Mistakes That Create Dark Bands

Mounting the LED too far behind the door frame

Many installs place LEDs deep inside. That seems safe. However, it causes the door edge to block the beam. You then get a dark vertical band near the front. Instead, the LED must sit closer to the door-side.

Using a single light strip instead of balanced lighting

One strip on one side cannot cover the full width evenly. Therefore, shadows form on the opposite side. This is common in wider display sections. Balanced lighting solves this quickly.

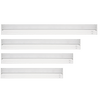

Wrong spacing between light sources causes stripes

When light strips have uneven gaps, the freezer shows bright spots and dark columns. Also, shelves will throw repeated shadows. So keep spacing consistent. Use a layout plan first.

Best LED Placement for Glass-Door Freezers

Side vertical placement for uniform door coverage

For most cases, vertical side mounting gives the best output. It lights products from top to bottom. It also reduces shelf shadows. This layout works best for refrigerated display case lighting in stores.

Also, side placement supports clean glass door freezer lighting because it follows the door height.

Top lighting placement (when it works & when it fails)

Top mounting can work in short coolers. But in tall freezers, it often fails. Why? Because the top beam cannot reach the lower shelves with enough strength. So the bottom looks dull. Shadow bands become stronger.

Dual-side lighting for high-end shadow-free look

If the freezer is wide, use dual-side strips. You can place LEDs on both sides. This reduces shadows. It also creates a balanced brightness. This is a strong option in commercial freezer lighting solutions where presentation matters.

How to Position LED Cooler Lights to Eliminate Hotspots and Shadow Lines

Ideal mounting point: near the front edge, not deep inside

Place the strip near the front inside edge. Do not push it to the back wall. The front position spreads light across the shelf face. It also reduces dark bands near the door.

So when you use LED strip lights for freezer doors, aim for front-edge mounting.

Distance guidelines from door and shelving

Keep the LED close, but not too close. If it touches the frame, glare can reflect on glass. If it is too far, shadows appear again.

A simple rule helps:

-

Keep the light 1–2 inches behind the door frame

-

Keep it 1–3 inches away from products

-

Avoid mounting directly above thick shelf lips

Angle adjustment tricks to spread light evenly

Angle matters as much as position. Even a small tilt can change results. So use angled channels or brackets.

Try these tips:

-

Tilt the LED slightly toward the product faces

-

Avoid aiming at the glass

-

Use a test shelf with products before final mounting

This is the most practical way to improve LED cooler lights placement.

Choosing the Right Beam Angle & Diffuser Lens for Even Cooler Lighting

Why wide beam angle reduces harsh lines

A wide beam spreads light smoothly. It fills gaps. It reduces line shadows. So avoid narrow optics when possible. For display coolers, wide beam lighting looks more uniform.

This is important for LED lighting for display coolers because customers view products through glass.

Best diffusers: frosted lens vs clear lens

A diffuser can remove harsh stripes fast. Frosted covers soften the beam. Clear covers stay brighter but can show hotspots. Therefore, frosted diffusers work better if shadow lines are your problem.

Anti-glare lighting to reduce reflection on glass doors

Glare makes shadows look worse. It also hides products behind reflections. So choose anti-glare fixtures or diffused strips. This improves product visibility and creates cleaner freezer display lighting.

Recommended Color Temperature & CRI for Display Freezers

5000K daylight for better product clarity

For most retail freezers, 5000K is a strong choice. It looks bright and clean. It also makes packaging and labels easy to read. That is why 5000K is widely used in cooler freezer LED lights installs.

CRI 80+ or CRI 90: what matters in retail freezers

CRI controls how real colors look. CRI 80 is fine for general use. But CRI 90 is better for premium displays. If the store sells high-end frozen products, CRI 90 can add value.

Avoiding “blue tint” effect in freezer displays

Some LEDs look too blue in cold environments. This happens with poor quality chips. It can make items look unnatural. So choose stable LEDs designed for cold temperatures. This is a key part of long-term commercial freezer lighting solutions.

Pro Lighting Layout Tips for Multi-Door Freezers

Best lighting layout for 2-door and 3-door freezers

For 2-door and 3-door setups, consistency is everything. Use the same strip type on each door section. Match the mounting height. Match the angle.

Also, ensure the light does not stop early at the top or bottom.

Layout for 4-door and 6-door glass freezer walls

In longer walls, voltage drop and poor planning create uneven brightness. So use proper drivers and power injection points. If one section looks dim, customers notice it instantly.

Matching brightness across sections (lumens consistency rule)

Use the same lumen output for each section. Do not mix different LED models. Also, avoid mixing different lens types. When brightness is consistent, the whole freezer wall looks neat and professional.

Conclusion

Shadow lines are not unavoidable. They happen due to poor placement, wrong optics, or bad angles. However, once you fix your layout, the display becomes clean and balanced.

Start with front-edge mounting. Then use wide beam lighting and diffused lenses. Also, keep spacing equal and brightness consistent. When done right, glass door freezer lighting looks even across every shelf. And with smart LED cooler lights placement, your freezer stops looking patchy.

In the end, better cooler freezer LED lights placement improves visibility, reduces product shadows, and supports stronger retail presentation.

Frequently Asked Questions

Q: Why do shadow lines appear in glass-door freezers?

A: Shadow lines usually happen due to wrong LED angle, narrow beam lighting, or shelf edges blocking light. Poor light placement makes dark bands.

Q: Where should LED lights be placed inside a glass-door freezer?

A: Mount LED strips near the front edge of the frame, not deep inside the cabinet. Side vertical placement gives the most even coverage.

Q: Can diffuser lenses reduce shadow lines in freezer lighting?

A: Yes, frosted diffusers spread light better and soften harsh beams. They help reduce stripes, hotspots, and dark patches inside the freezer.

Q: What is the best color temperature for freezer display lighting?

A: 5000K daylight is the most common for display freezers because it looks bright and clear. It also helps products appear clean and visible.

Q: Do I need dual-side LED lighting for commercial glass-door freezers?

A: If the freezer section is wide or has multiple doors, dual-side lighting gives balanced brightness. It reduces shadows and improves display quality.