In today's industrial landscape, safety is paramount, especially in hazardous environments where the risk of explosions is a constant concern. One critical aspect of ensuring safety in such areas is proper lighting. LED Explosion-Proof Lighting has emerged as a top choice for illuminating hazardous areas, but what standards govern its use? In this comprehensive guide, we will delve into the world of LED Explosion-Proof Lighting and explore the standards that ensure its reliability in hazardous locations.

Table of Contents

|

Introduction

The safety of workers and equipment in hazardous areas is a top priority for industries such as oil and gas, chemical manufacturing, and mining. One crucial aspect of ensuring safety in these environments is the quality of lighting. In this article, we will explore the world of LED Explosion-Proof Lighting and the standards that govern its use.

Understanding Hazardous Areas

Before diving into the specifics of lighting, it's essential to understand what constitutes a hazardous area. These areas are classified based on the presence of potentially explosive atmospheres, often caused by the presence of flammable gases or dust. Examples include oil refineries, chemical processing plants, and grain elevators.

The Importance of Adequate Lighting

In hazardous areas, visibility is often compromised due to various factors like dust, fog, or smoke. Adequate lighting is crucial for several reasons:

- Safety: Proper illumination reduces the risk of accidents, such as trips and falls, which can have severe consequences in hazardous locations.

- Productivity: Workers can perform tasks more efficiently and accurately with adequate lighting, improving overall productivity.

- Compliance: Many safety regulations mandate specific lighting requirements in hazardous areas.

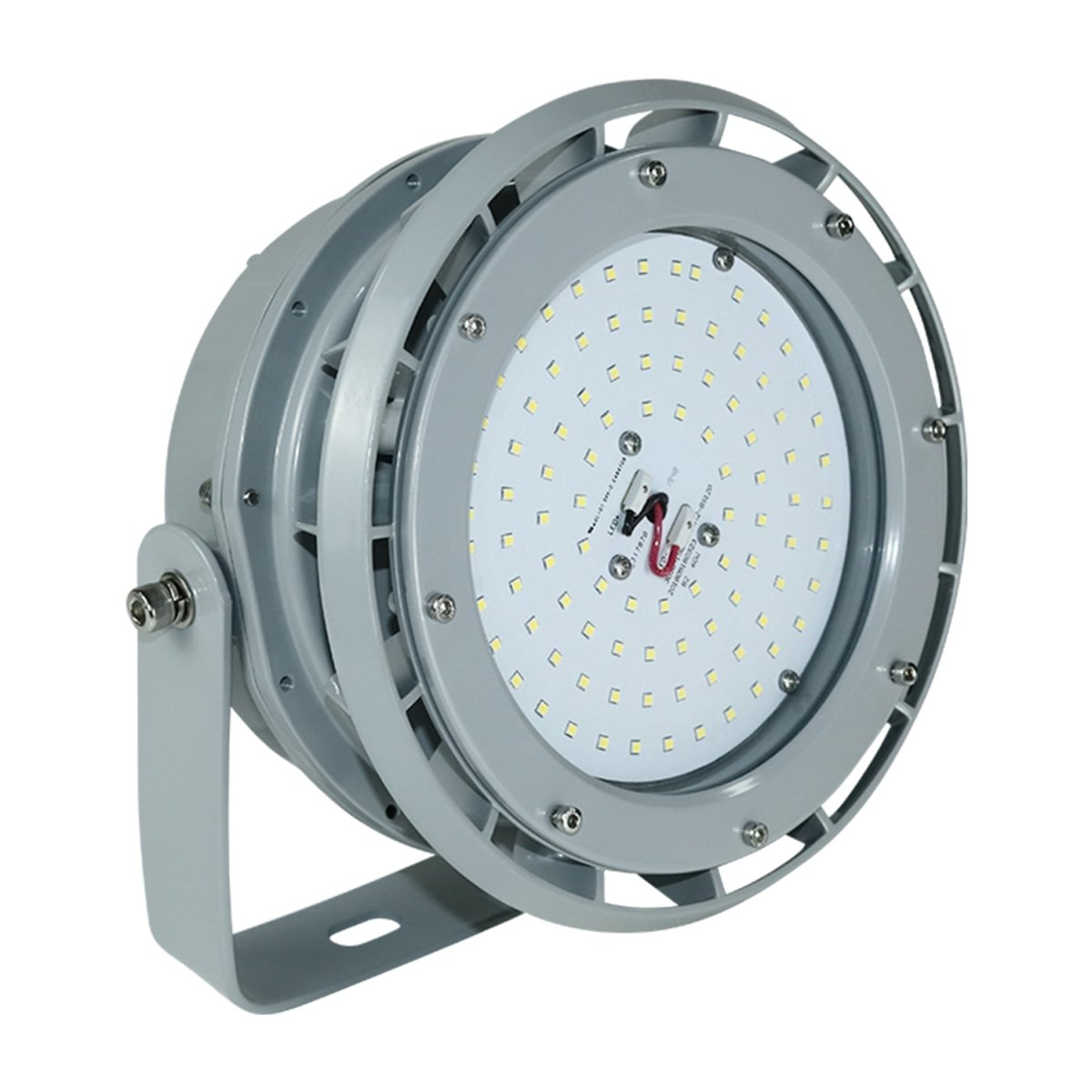

What is LED Explosion-Proof Lighting?

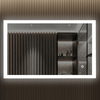

LED Explosion-Proof Lighting is a specialized lighting system designed to operate safely in hazardous environments. It is engineered to prevent the ignition of flammable substances in the surrounding atmosphere. LEDs are used due to their energy efficiency and durability, making them an ideal choice for this critical application.

The Standard for Explosion-Proof Lighting

Classifications

Explosion-Proof Lighting is classified into different groups and divisions based on the type of hazardous materials present. The classifications include:

- Class I: Locations where flammable gases or vapors are present.

- Class II: Locations with combustible dust.

- Class III: Locations with easily ignitable fibers or flying materials.

Each class has further divisions, and the choice of LED Explosion-Proof Lighting must align with the specific classification of the hazardous area.

Certifications

To ensure the safety and reliability of LED Explosion-Proof Lighting, various certification agencies, such as UL (Underwriters Laboratories) and ATEX (Atmosphères Explosibles), provide certifications. These certifications indicate that the lighting fixtures meet strict safety and performance standards.

Benefits of LED Explosion-Proof Lighting

The adoption of LED Explosion-Proof Lighting offers several advantages, including:

- Energy Efficiency: LEDs consume less energy compared to traditional lighting technologies, leading to cost savings.

- Durability: LEDs are robust and resistant to shock and vibration, ensuring a longer lifespan.

- Instant Illumination: LEDs provide instant and consistent illumination without warm-up time.

- Low Maintenance: LED fixtures require minimal maintenance, reducing operational costs.

Installation and Maintenance

Proper installation and regular maintenance are essential to ensure the continued reliability of LED Explosion-Proof Lighting. Only trained professionals should install these fixtures, and routine inspections must be carried out to identify and address any issues promptly.

Applications of LED Explosion-Proof Lighting

LED Explosion-Proof Lighting finds applications in various industries, including oil and gas, petrochemical, pharmaceuticals, and more. It is used in areas such as:

- Oil Rigs: Illuminating drilling platforms and refineries.

- Chemical Plants: Ensuring safety during chemical processing.

- Mining: Lighting tunnels and underground operations.

- Warehouses: Providing illumination in dusty environments.

Cost Considerations

While LED Explosion-Proof Lighting may have a higher upfront cost compared to traditional lighting, the long-term benefits in terms of energy savings and reduced maintenance expenses often outweigh the initial investment.

Comparing LED with Traditional Lighting

A comparison between LED and traditional lighting technologies highlights the superior performance of LEDs in hazardous areas. From energy efficiency to lifespan, LEDs outshine their counterparts.

Future Trends in Explosion-Proof Lighting

As technology continues to advance, we can expect further innovations in the field of explosion-proof lighting. These may include smart lighting systems, enhanced efficiency, and improved safety features.

Conclusion

LED Explosion-Proof Lighting plays a vital role in ensuring safety in hazardous areas. Understanding the standards and benefits of this technology is crucial for industries operating in such environments. By investing in the right lighting solutions, companies can protect their workforce and assets while optimizing operations.

FAQs

-

What are hazardous areas?

- Hazardous areas are locations where the presence of flammable gases, dust, or other potentially explosive materials poses a safety risk.

-

How does LED Explosion-Proof Lighting work?

- LED Explosion-Proof Lighting is designed to prevent the ignition of flammable substances in the surrounding atmosphere. It uses energy-efficient LEDs for illumination.

-

Are there any energy-saving benefits to using LED Explosion-Proof Lighting?

- Yes, LEDs are energy-efficient and consume less electricity, leading to cost savings in the long run.

-

Can LED Explosion-Proof Lighting be retrofitted into existing installations?

- In many cases, yes. However, it's essential to ensure compatibility and safety when retrofitting LED Explosion-Proof Lighting.

-

What are the key features to look for when choosing LED Explosion-Proof Lighting?

- When selecting LED Explosion-Proof Lighting, consider factors such as certification, classification, energy efficiency, and durability.