Switching to LED integrated tube lights looks like an easy upgrade. You replace the old tube. You flip the switch. The job is done.

However, many people run into problems after buying. The tube does not turn on. The light flickers. The color looks wrong. Or the brightness feels low.

That is frustrating. It also wastes time and money.

So, this guide breaks down the top mistakes people make when moving to LED integrated tubes. It also provides a simple way of avoiding them. This will assist you in selecting the appropriate tubes and installing them correctly whether you are planning an update for a garage, office, warehouse, or retail area.

What Are (And Why People Switch to Them?)

What “Integrated” Actually Means

An integrated tube has the LED chips and driver built into one unit.

So it does not rely on the old fluorescent system to function the same way.

That matters because some upgrades need wiring changes. Therefore, you must know what type of setup you are working with before buying.

Benefits of LED Integrated Tubes

People switch to LED integrated tube lights because the upgrade solves common lighting problems fast. Also, it makes maintenance easier.

Key benefits include:

-

Lower energy use and fewer power issues

-

Instant ON with no warm-up time

-

Better lifespan compared to fluorescent tubes

-

Less maintenance for commercial buildings and long-run savings

So, when the correct tube is picked, the results are clean and consistent.

LED Integrated Tubes vs Traditional Fluorescent Tubes

Fluorescent Tube Issues Need to be Fixed

Fluorescent tubes still exist in many buildings. However, they come with repeated problems.

Common fluorescent issues:

-

Flickering

-

Slow start, especially in cold weather

-

Higher power bills

-

Frequent replacement

Because of these issues, many building owners want something more stable.

LED Integrated Tube Upgrade Advantage

LED integrated tubes solve the common pain points quickly. In fact, the change feels noticeable on day one.

Key advantages:

-

Stable brightness with fewer lighting complaints

-

No buzzing sounds from old ballasts

-

Better light quality in work areas

So, if you want consistent performance, an integrated tube setup makes sense.

Mistake #1 – Not Checking Ballast Compatibility Before Buying

This is the biggest mistake. And it is also the most common.

Ballast Compatible vs Ballast Bypass (Big Confusion)

Many buyers assume all LED tubes work the same. They do not.

Some tubes work with a ballast. Others require a ballast bypass LED tube setup.

So, before buying, you must confirm what your fixture supports. Otherwise, you may order the wrong tube type.

What Happens If You Choose Wrong Type

When the wrong type is installed, the performance becomes unstable.

For example, the tube may flicker. It may not turn on at all. It can also reduce lifespan due to stress on the internal driver.

So, this is not a small issue. It can ruin the full upgrade.

LEDMyPlace Tip: Confirm Fixture Type Before Checkout

Before ordering, use this quick buyer checklist:

-

Check if the fixture has an active ballast

-

Confirm if your upgrade is plug-and-play or bypass wiring

-

Match the tube type to the fixture type

-

Confirm voltage rating for the location

This step reduces returns and saves money. It also makes the upgrade smooth.

Mistake #2 – Choosing the Wrong Tube Size or Pin Type

Even if the tube type is correct, size errors still happen.

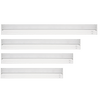

Common Sizes (2ft / 4ft / 8ft)

Many buildings use 4ft tubes. However, some spaces use 2ft or 8ft.

Because of that, ordering the wrong size is easy.

So always measure the tube length before you buy. Do not guess.

Single Pin vs Double Pin (R17d vs G13)

Pins matter. And they must match the fixture sockets.

A mismatch means the tube will not fit, even if it is the right length.

Here’s the simple rule:

-

G13 = double pin base

-

R17d = single pin base

So check the base. Then order.

Check Fixture + Ordering Match

Use this quick checklist:

-

Tube length matches the fixture

-

Pin type matches the lampholders

-

Fixture is rated for the tube type

-

Your order includes the correct mounting support

This prevents time wastage during the installation process

Mistake #3 – Picking the Wrong Color Temperature (4000K vs 5000K)

Color temperature changes the feel of the room. So it is a major decision.

4000K Neutral White – Best for Offices & Retail

4000K vs 5000K LED tube selection often depends on comfort.

4000K feels balanced. It looks clean but not harsh.

Best spaces for 4000K:

-

Offices

-

Retail stores

-

Classrooms

-

Reception areas

So, it supports productivity without looking too cold.

5000K Daylight – Best for Warehouses & Garages

5000K looks brighter and more crisp. It improves visibility.

Therefore, it works better for task-heavy areas.

Best spaces for 5000K:

-

Warehouses

-

Garages

-

Workshops

-

Storage rooms

So, it improves detail and safety.

Mistake People Make

Many people pick too cool for comfort. Or they pick too warm for work.

As a result, the space feels wrong even if brightness is high.

So, choose color temperature based on the room purpose.

Mistake #4 – Ignoring Lumens and Only Comparing Watts

Watts do not tell you brightness. Lumens do.

Lumens = Brightness

Lumens show how much visible light the tube produces.

So always compare lumens first.

Ideal Lumen Ranges for Common Spaces

If you pick based on space type, the result feels correct.

Typical needs:

-

Warehouse: higher lumens for strong visibility

-

Office: medium lumens for comfort

-

Parking/garage: bright neutral output for safety

So, matching lumens to the job avoids poor lighting results.

LEDMyPlace Tip: Choose Lumens Based on Ceiling Height

Ceiling height matters. Higher ceilings need stronger output.

So do not use the same lumen level in every building.

As a simple rule:

-

Higher ceiling = higher lumens needed

-

Lower ceiling = lower lumens still looks bright

This improves performance without overbuying.

Mistake #5 – Poor Installation/Wiring Mistakes That Reduce Performance

Even the best tube fails if installation is messy.

Wrong Wiring Can Damage the Tube

Bad wiring can cause short circuits. It can also damage drivers.

So safety must come first.

This is especially important during LED integrated tube installation for commercial upgrades.

Common Installation Mistakes

Here are common problems seen during upgrades:

-

Mixing old wiring with bypass type setup

-

Leaving loose connections

-

Skipping fixture inspection steps

-

Not using an electrician in commercial spaces

So, do not rush the wiring stage.

Best Practice for Safe LED Tube Installation

Follow this safety checklist:

-

Turn power off before starting

-

Read the wiring diagram for the tube type

-

Confirm fixture rating and voltage

-

Tighten connections and secure wiring

This enhances long-term stability and safeguards the tube.

Mistake #6 – Not Replacing Bad Fixtures or Old Components

Some fixtures are too worn out to reuse.

Old sockets may be loose. Wiring may be brittle. Also, housing may have heat damage.

So even if the tube is new, performance can still suffer.

Before installation:

-

Inspect lampholders for wear

-

Check for burn marks or loose wires

-

Replace broken parts before the upgrade

This prevents random failures later.

Mistake #7 – Not Planning the Upgrade Room-by-Room

Many people upgrade the whole building without a plan. That causes inconsistency.

One area looks bright. Another feels dim. Color temperature changes between rooms.

So the building looks uneven.

Instead, plan the upgrade:

-

Use one color temp per zone

-

Standardize lumen level by room type

-

Keep tube type consistent

This makes lighting uniform and professional.

Conclusion

Switching from fluorescent to LED integrated tube lights is a smart move.

However, the best result depends on the details.

So, remember the key steps:

-

Confirm fixture type before buying

-

Select the appropriate pin style and size.

-

Decide between 4000K and 5000K based on the space

-

Compare lumens, not watts

-

Install safely and wire correctly

Also, understand the difference between a tube that works with a ballast and a ballast bypass LED tube setup. That one detail prevents most upgrade problems.

Frequently Asked Questions

Q: Are LED integrated tube lights better than fluorescent tubes?

A: Yes, they start instantly and stay steady without flicker. They also reduce energy use and last longer in most setups.

Q: Do LED integrated tubes need a ballast?

A: Some do, but many don’t. Always check if your tube is ballast compatible or a ballast bypass LED tube.

Q: What is ballast bypass LED tube wiring?

A: Ballast bypass means you remove or disconnect the ballast. Then the tube runs directly on line voltage with the correct wiring.

Q: What is the most common LED integrated tube installation mistake?

A: Buying the wrong type for your fixture is the top mistake. It can cause flicker, no power, or early tube failure.

Q: LED integrated tube vs fluorescent tube: what changes the most?

A: LED gives cleaner, stable light with no buzzing or delay. Fluorescent tubes often flicker and require more maintenance.