Do you know what are back-lit LED Panels and why they are better? If no, let us help you to know everything about back-lit LED Panels.

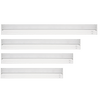

There are two types of LED Panels: Back-lit LED Panels & Edge-lit LED Panels, in various sizes; the only difference is the location of the LEDs and how the light gets dispersed.

A back-lit LED panel arrangement of LEDs fixed on a horizontal plate through a diffuser shining vertically down. They are also known as direct-lit panels.

As the name suggests, an edge-lit LED Panel is made of a row of LEDs attached to the edge of the panel, shining horizontally. In addition, the light illuminates downwards through a diffuser. They are also known as side-lit panels.

Pros of Back-lit LED Panels

- Thin compared to other LED Panels

- Higher energy efficiency

- Cut-out the costs of manufacturing

- More light output

- Consistent and powerful illumination

- Easy to install

- Prevents discoloration of diffuser

To know more benefits of Back-lit LED Panels, let’s compare them with Edge-lit LED Panels. This will make clearer why Back-lit LED Panels are so popular.

Back-lit vs Edge-lit LED Panels

Both the LED Panels have their own pros and cons, but as we mentioned earlier, Back-lit LED panels are still better.

Reasons why Edge-lit LED Panels were chosen:

- Edge-lit was one of the best ways to diffuse the light that avoided the risk of bright spots.

- The presence of PMMA ensured that the diffuser alone was not responsible for the even distribution of light. So low-cost material was used; the only condition was that it should not deteriorate with time.

- It worked better with the various beam angles without the use of lenses.

- The rear part of the edge-lit LED Panels can be lightweight as the heat will dissipate from the LED chips, and the driver can also be placed here.

But with time, the drawbacks of this method become more visible. Acrylic is the apt material for an Edge-lit material that is quite expensive, so often, cheaper material is used. However, if it is not mixed with the UV stabilizing additives, that material turns yellow over time. This turns the light output into dull yellow, and the center of the panel darkens.

Technical advances bring in a new generation of LED Panels, and they are Back-lit LED Panels. They are far more efficient with lower costs than edge-lit LED Panels.

- LEDs have become more efficient, and the back-lit designs are no hotter, so the driver cannot be placed on the rear.

- PMMA Lenses are cheaper and modern adhesives have fixed them safely to produce an even light distribution, reducing the risk of falling off. This was a big challenge with the old LED Panels.

- The new and modern PS diffusers are available, which are less expensive and more effective, so the double action of the combination of diffusers is no longer required.

- Back-lit panels are designed with a PMMA lens that means more potential energy savings than edge-lit designs.

The lighting industry has now accepted the back-lit panels more than edge-lit panels because back-lit panels are the lowest cost and most durable.