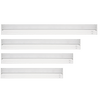

In today's world, LED panels have become increasingly popular due to their energy efficiency and long lifespan. However, one common issue that users may encounter is the yellowing of LED panels over time. This phenomenon can be frustrating and raises questions about the durability and quality of these lighting solutions. In this article, we will explore the reasons behind LED panel yellowing and discuss how to prevent or mitigate this problem. So, let's dive in and discover why LED panels go yellow.

Table of Contents

|

Introduction

LED (Light Emitting Diode) panels are a popular lighting solution used in various applications such as residential, commercial, and industrial settings. They offer numerous benefits, including energy efficiency, long lifespan, and environmental friendliness. However, it is not uncommon for LED panels to develop a yellow tint over time, which can affect their overall performance and aesthetics. To understand why this happens, it is crucial to delve into the science behind LED panels and the factors that contribute to their yellowing.

Understanding LED Panels

LED panels are composed of an array of light-emitting diodes that produce illumination when an electrical current passes through them. These diodes emit light in different colors, including white light. The white light is achieved by combining red, green, and blue (RGB) diodes or through phosphor-coated LEDs that convert blue light into white light. The latter is more commonly used in LED panels.

Causes of LED Panel Yellowing

1. Heat Exposure

Heat is one of the primary culprits behind LED panel yellowing. When LED panels operate for extended periods, they generate heat. Excessive heat can degrade the materials used in the panel, including the phosphor coating, which can result in color shifts and a yellowish hue. Additionally, poor heat dissipation due to inadequate ventilation or improper installation can exacerbate this problem.

2. UV Radiation

UV radiation, particularly from sunlight, can cause LED panels to yellow over time. The UV rays can degrade the phosphor coating, leading to a color shift. This issue is more prevalent in LED panels that are exposed to direct sunlight or strong artificial UV light sources.

3. Material Degradation

Over time, the materials used in LED panels can undergo degradation due to various factors such as exposure to chemicals, moisture, and pollutants. This degradation can affect the performance and color stability of the phosphor coating, leading to yellowing.

Effects of Yellowing

Yellowing of LED panels can have several negative effects. Firstly, it can alter the color rendering of the light emitted by the panels, resulting in a less accurate representation of colors. This can be particularly problematic in applications where color accuracy is crucial, such as art galleries, retail stores, or photography studios. Secondly, the yellowing can diminish the overall brightness and efficacy of the LED panels, reducing their effectiveness in providing adequate illumination.

Preventive Measures

To prevent or minimize LED panel yellowing, several preventive measures can be taken:

1. Proper Ventilation and Heat Dissipation

Ensuring proper ventilation and heat dissipation is crucial for maintaining optimal operating temperatures. Adequate airflow around the LED panels can help dissipate excess heat, reducing the risk of material degradation and yellowing. Proper installation and the use of heat sinks or cooling fans can contribute to effective heat management.

2. UV Protection Films

Applying UV protection films or coatings to the LED panels can help mitigate the harmful effects of UV radiation. These films act as a barrier, reducing the UV exposure and minimizing the chances of yellowing caused by UV degradation.

3. Quality Assurance and Material Selection

Choosing LED panels from reputable manufacturers known for their quality assurance practices can help ensure better performance and longevity. High-quality materials and robust manufacturing processes can contribute to enhanced resistance against yellowing.

4. Regular Cleaning and Maintenance

Regular cleaning and maintenance of LED panels are essential to prevent the buildup of dust, dirt, or other contaminants that can contribute to yellowing. Using appropriate cleaning methods and products recommended by the manufacturer can help maintain the panels' performance and appearance.

Conclusion

LED panels are a popular lighting solution appreciated for their efficiency and longevity. However, yellowing can occur over time, affecting their performance and visual appeal. Heat exposure, UV radiation, and material degradation are key factors contributing to LED panel yellowing. By implementing preventive measures such as proper ventilation, UV protection, material selection, and regular maintenance, users can prolong the lifespan and maintain the color integrity of LED panels.

Frequently Asked Questions (FAQs)

-

Q: Can all LED panels go yellow? A: While yellowing can occur in some LED panels, it is not a universal issue. Factors such as quality, operating conditions, and maintenance practices can influence the likelihood of yellowing.

-

Q: How long do LED panels typically last before yellowing becomes noticeable? A: The time it takes for yellowing to become noticeable can vary depending on several factors, including usage patterns, environmental conditions, and the quality of the LED panels. In general, it may take several years before significant yellowing becomes apparent.

-

Q: Can yellowed LED panels be restored to their original color? A: In most cases, yellowed LED panels cannot be restored to their original color. Preventive measures are crucial to minimize yellowing, as restoration options are limited once the degradation occurs.

-

Q: Are there any health risks associated with yellowed LED panels? A: Yellowing of LED panels is primarily a cosmetic issue and does not pose significant health risks. However, it is advisable to maintain optimal lighting conditions for visual comfort and well-being.

-

Q: Are there specific cleaning products recommended for LED panel maintenance? A: It is best to refer to the manufacturer's guidelines for specific cleaning products and methods suitable for LED panel maintenance. Using inappropriate cleaning agents can damage the panels and contribute to yellowing.