Table of Contents

|

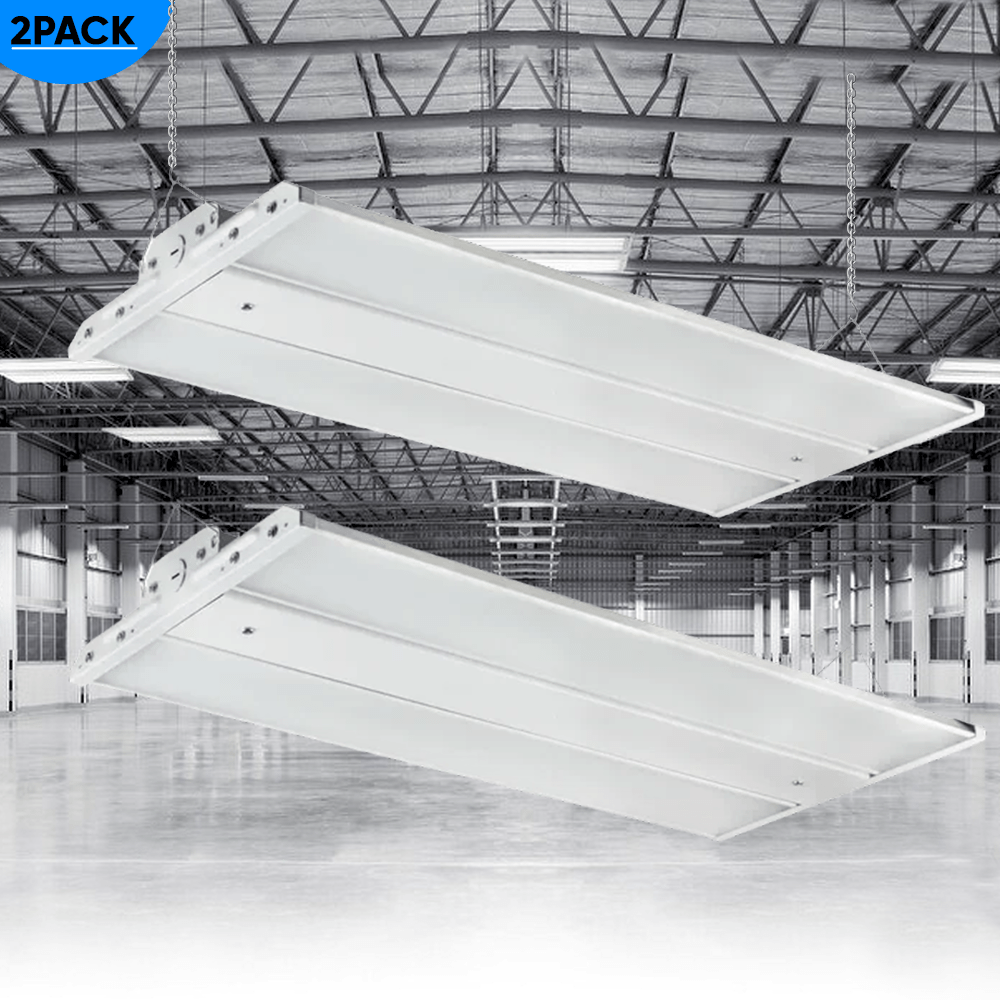

Warehouses are vital hubs of activity in any industry, bustling with movement and operations around the clock. Amidst the hustle, ensuring proper lighting is often overlooked, yet it plays a crucial role in maintaining productivity, safety, and efficiency within these spaces. In this guide, we'll delve into the world of lumens and explore how to determine the ideal lighting requirements for your warehouse.

Understanding Lumens

Before we delve into the specifics, let's grasp the concept of lumens. Lumens measure the total amount of visible light emitted by a light source, representing its brightness. Unlike watts, which indicate energy consumption, lumens focus solely on the light output. In the context of Warehouse Lighting, lumens play a pivotal role in ensuring adequate brightness levels for optimal functionality.

Factors Influencing Lumens Needed for Warehouse Lighting

Several factors come into play when determining the appropriate lumens for warehouse lighting:

Size and Layout of the Warehouse

The size and layout of your warehouse dictate the distribution of light. Larger warehouses with extensive shelving or storage racks may require more luminaires strategically placed to eliminate dark spots and ensure uniform illumination.

Ceiling Height

Ceiling height directly impacts the spread of light. Taller ceilings necessitate luminaires with higher lumen output to adequately illuminate the space below.

Tasks Performed in the Warehouse

Different tasks carried out within the warehouse demand varying levels of illumination. For instance, detailed assembly work may require brighter lighting compared to general storage areas.

Desired Light Level

The intended purpose of the warehouse also influences the desired light level. Warehouses serving as distribution centers may require brighter lighting to enhance visibility for inventory management and order picking.

Calculating Lumens for Warehouse Lighting

Determining the required lumens involves a simple calculation based on the square footage of the warehouse and the desired light level measured in foot-candles. The formula is as follows:

Lumens = Area(sq.ft.) × Desired Foot−Candles

Let's consider an example to illustrate this calculation:

Suppose we have a warehouse with an area of 10,000 square feet and a desired light level of 30 foot-candles. Using the formula:

Lumens = 10,000sq.ft. × 30foot−candles = 300,000lumens

This means that to achieve a light level of 30 foot-candles in a 10,000 square feet warehouse, we would need luminaires with a total output of 300,000 lumens.

Common Mistakes to Avoid When Determining Lumens

While calculating lumens, several pitfalls must be avoided:

Underestimating Lumens Needed

Underestimating the required lumens can result in insufficient lighting, leading to dim areas and compromised visibility, affecting productivity and safety.

Ignoring Task-Specific Lighting Requirements

Neglecting task-specific lighting requirements may lead to inadequate illumination for certain activities, impacting efficiency and accuracy.

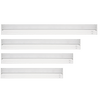

Choosing the Right LED Warehouse Lighting

LED lighting stands out as the preferred choice for warehouse illumination due to its numerous advantages:

- Efficiency and Brightness: LED luminaires offer high lumen output while consuming minimal energy, resulting in cost savings and reduced environmental impact.

- Compatibility with Warehouse Conditions: LED lights are durable and withstand the harsh conditions typically found in warehouses, including temperature fluctuations and vibration.

Benefits of Using LED Lighting in Warehouses

The adoption of LED lighting in warehouses brings forth a multitude of benefits:

- Energy Efficiency: LED lights consume significantly less energy than traditional lighting options, leading to substantial cost savings on electricity bills.

- Longevity: LED luminaires have an extended lifespan, reducing maintenance costs and downtime associated with frequent bulb replacements.

- Improved Visibility and Safety: The bright, uniform illumination provided by LED lighting enhances visibility, reducing the risk of accidents and improving overall safety within the warehouse environment.

Conclusion

In conclusion, determining the appropriate lumens for warehouse lighting is essential for creating a conducive work environment conducive to productivity and safety. By considering factors such as warehouse size, ceiling height, and task requirements, alongside the benefits of LED lighting, businesses can optimize their lighting solutions for maximum efficiency and effectiveness.

FAQs

-

What if my warehouse has varying ceiling heights?

- In cases of varying ceiling heights, it's advisable to consult with lighting experts who can recommend customized solutions tailored to your specific requirements.

-

Are there any government regulations regarding warehouse lighting?

- Yes, certain jurisdictions may have regulations governing warehouse lighting to ensure adequate levels of illumination for worker safety. It's essential to familiarize yourself with local regulations to remain compliant.

-

Can I retrofit existing lighting fixtures with LED bulbs?

- Yes, many existing lighting fixtures can be retrofitted with LED bulbs, offering a cost-effective way to upgrade to more energy-efficient lighting.

-

Do LED lights emit heat like traditional bulbs?

- LED lights produce significantly less heat compared to traditional bulbs, making them safer to use and reducing the strain on HVAC systems in warehouses.

-

How often do LED lights need to be replaced?

- LED lights have an average lifespan of 50,000 to 100,000 hours, significantly longer than traditional bulbs, resulting in reduced maintenance and replacement costs.