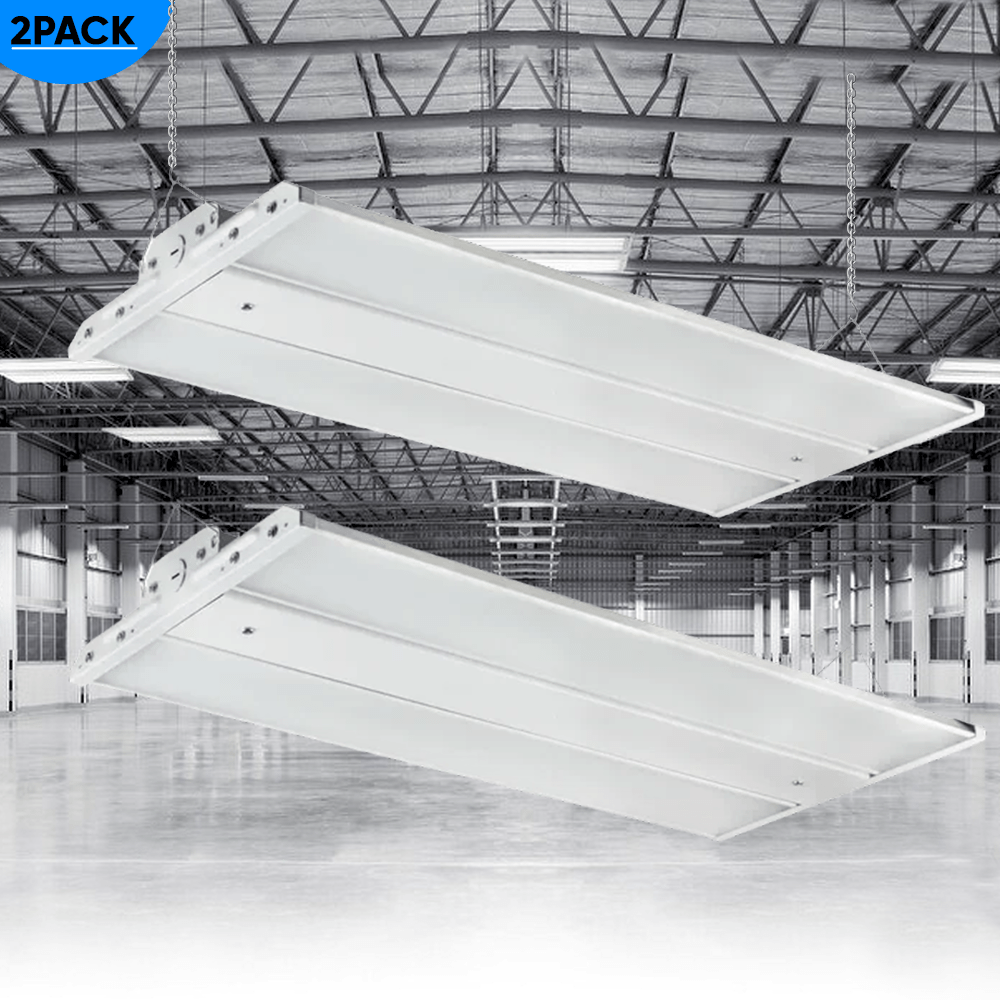

On the optimization of a warehouse, lighting acts as the most significant aspect. Proper LED lighting in a warehouse improves productivity and safety and enhances energy efficiency. Determining how bright a warehouse should be depends on several criteria such as work nature, ceiling height, and specific industry standards.

Understand Warehouse Lighting Brightness

A warehouse's brightness is measured in lux, which is the amount of light per square meter. Depending upon the task, various tasks demand different lux levels to be efficient and safe.

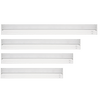

Recommended Lux Levels for Warehouses:

General Storage Areas: 100–200 lux

- General storage of non-critical goods, where employees do not need high precision.

Packing and Sorting Areas: 300–500 lux

- Tasks that require higher visibility, such as reading labels or handling fragile items.

Inspection or Quality Control Areas: 500–750 lux

- These areas require high precision, so brighter lighting is necessary for accurate inspections.

Heavy Machinery Zones: 200–300 lux

- This provides enough visibility for operators to work safely and efficiently.

Why LED Warehouse Lighting?

LED Warehouse Lighting is a very smart choice for several reasons:

- Energy Efficiency: LEDs consume 75% less energy compared to traditional lighting options such as fluorescent or halogen lights.

- Longer Lifespan: LED lights last much longer, reducing maintenance costs and downtime.

- Better Illumination: They offer uniform light distribution, no dark spots, and increase visibility.

- Brightness: LEDs are also dimmable, meaning that their brightness levels can be adjusted to meet the needs of specific tasks.

Factors Affecting Warehouse Brightness

Ceiling Height: Warehouses with higher ceilings require more lumens for the provision of sufficient brightness on the floor. High bay LED lights are remarkably effective for these spaces.

Reflective Surfaces: Walls and floors with light colors or reflective materials can enhance brightness by reflecting light, thereby reducing the need for too many fixtures.

Task Type: Always consider the type of work performed in the area. Precision tasks demand higher brightness levels.

Natural Light Availability: Using skylights or windows can minimize the dependency on artificial lighting at the sky during the daytime.

Warehouse Brightness FAQs

Q1: How many LED lights do I need for my warehouse?

A: Calculate the square footage of your warehouse. Decide on your lux level according to your tasks, then determine how many total lumens you need. Divide that by your lumen output LED and multiply by the number of fixtures.

Q2: What color temperature is best for warehouse lighting?

A: Ideal color temperature to be used in warehouses ranges from 4000K to cool white (5000K) that is nearest daylight and improves concentration and vision.

Q3: Is an LED acceptable for use within cold storage warehouses?

A: LED's can even work great at colder temperature, so perfect for cold-storage applications

Q4: Are there brightness regulations set for warehouse lighting?

A: Yes, according to OSHA and other safety organizations, specific lighting levels are recommended according to workplace safety standards. Apply these to meet the standard.

Conclusion

Good lighting is essential for a safe and productive warehouse environment. LED warehouse lighting is best for optimal brightness, efficiency, and cost-effectiveness. Assess your warehouse needs and invest in quality lighting solutions to create a bright, efficient workspace.

High-quality, LED warehouse lighting options at LEDMyplace: brighten up your warehouse today!