Lighting should be the priority in any industrial premise where workers are surrounded by potentially harmful types of equipment and tools. Some common industrial spaces where safety is a must include warehouses, factories, welding shops, etc. For example, in a welding shop, it is vital to install the best welding shop lighting fixtures to get the safest environment possible. With a simple upgrade to the overall lighting, any welding shop owner can prevent many work accidents and mistakes caused by poor visibility. Choosing a welding shop lighting fixture is not a big deal, as you just need to know which one suits your place’s requirements.

Consider a Suitable Lumens Output

Considering the total lumens output of the welding shop lighting fixture you are going to use is necessary. It confirms that the lighting fixture is suitable to light up the entire place without any hassle. Well, the lumen is a measuring unit that shows the brightness level emitted by a light source. So far, LED shop lighting fixtures are the apt choice to illuminate industrial applications. Simply, you don’t want to invest in a light source that is incapable of meeting your lighting requirements. Thus, you should ensure that the one you are supposed to purchase is appropriate to deliver high lumens output.

A well-lit application can easily keep all the mistakes and workplace mishaps away with the help of proper visibility. Therefore, it is highly recommended to maintain high visibility to promote a safe environment for workers. Plus, it also encourages workers to boost their productivity and stay focused without facing any dark spots throughout the area.

Long-Lasting Welding Shop Lighting Fixtures are Beneficial

When it comes to longevity, LED welding shop lighting fixtures are considered the ideal ones. Generally, they are widely popular as advanced lighting technology, ensuring that they can last for a minimum of 50,000 hours. Along with the long lifespan, the lights will eliminate the replacement cost as well. In a welding shop, the replacement and maintenance of a lighting fixture can be a daunting and expensive task. However, the lights are specially designed to withstand different conditions and last for a long. So you do not have to worry about frequent maintenance and overall utility cost. With these advanced lighting fixtures, you will effortlessly save money and time spent on maintenance and replacement.

How Many Options of LED Lights are Suited for Industrial Lighting?

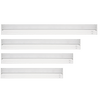

LED lights have numerous options to light up a welding shop or any other industrial premise. Usually, the collection of welding shop lighting fixtures includes UFO high bay lights, linear high bay lights, vapor tight high bay lights, and industrial LED strip lights. This is because they are considered more valuable alternatives to traditional lighting fixtures. Well, these types of lights are suitable for different kinds of applications where you need energy-efficient lighting and durable and long-lasting fixtures. In addition, they have an accurate beam angle to disperse quality brightness throughout the area. Along with this, the advanced lights do not need any warm-up time to reach the highest brightness level. Thus, they are the best-suited option for industrial lighting.

Which Type of Lighting do you want on your Premise?

Before you decide on the lighting fixture, you should confirm which type of lighting you want in your place. Normally, two types of lighting are mostly found in commercial buildings, which are general and task lighting. Here, you will understand both types of lighting in detail.

General Lighting

General lighting is commonly known as ambient lighting, which provides visibility throughout the shop. Usually, this type of lighting is used to provide overhead lighting that removes blind spots by covering a wide area with high illumination. Also, general lighting should be bright and evenly distributed because it is directed to the entire area and designed to cover a comprehensive location.

Task Lighting

Task lighting refers to a light designed for fitting certain places where specific lighting is required. This type of lighting is commonly used when you need to focus on a particular task. For example, task lighting is a basic need in welding shops or some other commercial places. Also, task lighting should be brighter than general lighting because it is specifically directed to areas where you are performing the task.

These are some common tips that you can follow to choose the best lighting fixtures for your commercial place. Usually, you must consider all the key points that help you get the desired lighting throughout your application.

1 comment

i would like more info on your lighting