TABLE OF CONTENTS

|

Introduction

In the bustling world of warehouses and distribution centers, the significance of proper lighting cannot be overstated. Beyond mere illumination, strategically planned lighting systems contribute to productivity, safety, and overall operational efficiency. This article delves into the essential lighting requirements for warehouses, exploring various factors, technologies, and design considerations to ensure optimal lighting solutions.

Types of Warehouse Lighting

General Illumination

General illumination serves as the primary source of light, illuminating the entire warehouse space uniformly. It facilitates basic tasks such as navigating aisles, locating inventory, and conducting routine operations.

Task Lighting

Task lighting targets specific work areas within the warehouse, providing focused illumination for detailed tasks such as packaging, sorting, and quality control. This type of lighting enhances visibility and reduces eye strain among workers.

Emergency Lighting

Emergency lighting is critical for maintaining visibility during power outages or other emergency situations. It includes backup lighting systems and exit signs to guide occupants safely out of the facility.

Factors Influencing Warehouse Lighting

Warehouse lighting requirements are influenced by various factors, including:

-

Warehouse Layout and Design: The size, shape, and layout of the warehouse dictate the placement and configuration of lighting fixtures to ensure adequate coverage.

-

Nature of Operations: Different warehouse activities, such as storage, picking, and loading, may require varying levels of illumination tailored to specific tasks.

-

Safety Regulations: Compliance with safety standards and regulations mandates proper lighting levels to minimize accidents and ensure a secure working environment.

Key Considerations for Warehouse Lighting

Energy Efficiency

Opting for energy-efficient lighting solutions not only reduces operational costs but also aligns with sustainability goals. LED lighting, in particular, offers significant energy savings and longevity compared to traditional lighting technologies.

Maintenance Requirements

Choosing lighting fixtures that are easy to maintain and repair is essential for minimizing downtime and ensuring continuous operation. Accessible fixtures and long-lasting components contribute to lower maintenance costs in the long run.

Light Distribution and Uniformity

Achieving uniform light distribution across the warehouse floor minimizes shadows and glare, creating a comfortable and visually consistent environment for workers. Properly designed lighting layouts account for height variations and obstructions to maintain consistent brightness levels.

Popular Lighting Technologies

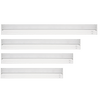

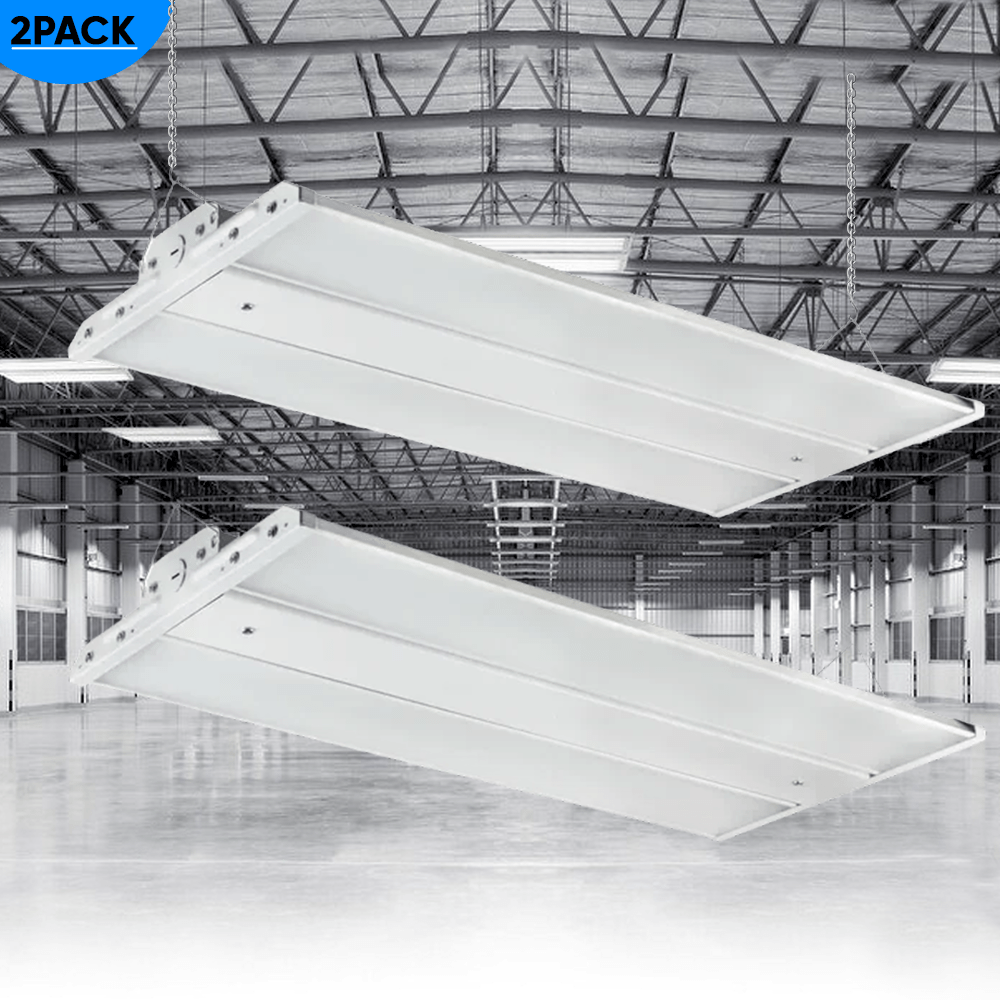

LED Lighting

LED (Light Emitting Diode) lighting has revolutionized the warehouse lighting landscape with its energy efficiency, long lifespan, and superior performance. LED fixtures provide bright, uniform illumination while consuming significantly less energy than traditional lighting sources.

High-Intensity Discharge (HID) Lighting

HID lighting, including metal halide and high-pressure sodium lamps, has been a staple in warehouse lighting for decades. Although less energy-efficient than LEDs, HID fixtures offer high lumen output and are suitable for large-scale applications.

Fluorescent Lighting

Fluorescent lighting remains a cost-effective option for warehouses, offering moderate energy savings and widespread availability. While not as efficient as LEDs, fluorescent fixtures are still utilized in areas where upfront costs are a primary concern.

Lighting Design Tips

Proper Placement of Fixtures

Strategic placement of lighting fixtures ensures uniform illumination throughout the warehouse while minimizing glare and shadows. Mounting fixtures at optimal heights and angles maximizes light distribution and enhances visibility.

Use of Motion Sensors

Incorporating motion sensors into lighting systems helps conserve energy by automatically adjusting illumination levels based on occupancy. Dimming or turning off lights in unoccupied areas reduces energy consumption without compromising safety or functionality.

Incorporating Natural Light

Where feasible, leveraging natural light through skylights, windows, or translucent roofing panels supplements artificial lighting, reducing reliance on electrical fixtures during daylight hours. Natural light also enhances employee morale and well-being by providing a connection to the outdoors.

Benefits of Optimal Warehouse Lighting

Enhanced Productivity

Well-lit work environments promote productivity by reducing errors, increasing accuracy, and fostering a sense of alertness among employees. Adequate lighting also facilitates efficient task completion, leading to higher throughput and operational efficiency.

Improved Safety

Properly illuminated warehouses minimize the risk of accidents and injuries by enhancing visibility and reducing tripping hazards. Clear visibility of signage, equipment, and emergency exits ensures rapid response in emergency situations, mitigating potential risks.

Cost Savings

Investing in energy-efficient lighting solutions translates into long-term cost savings through reduced electricity consumption and lower maintenance expenses. The longevity of LED fixtures minimizes replacement and maintenance costs, further bolstering the financial benefits.

Common Challenges and Solutions

Glare and Reflections

Glare and reflections from lighting fixtures can cause discomfort and visual impairment for workers. Utilizing diffusers, baffles, or directional lighting helps minimize glare while optimizing light distribution for task-specific areas.

Temperature Control

Traditional lighting sources such as HID lamps generate significant heat, contributing to thermal discomfort and increased cooling costs. LED lighting produces minimal heat output, reducing the strain on HVAC systems and maintaining comfortable working conditions.

Upgrading Existing Lighting Systems

Retrofitting outdated lighting systems with energy-efficient LED fixtures offers a cost-effective solution to improve illumination quality and reduce energy consumption. Government incentives and rebates may also be available to offset the upfront costs of upgrades.

Case Studies

Successful Implementation of Warehouse Lighting Solutions

Several companies have realized tangible benefits from upgrading their warehouse lighting systems. Case studies showcasing improved productivity, energy savings, and employee satisfaction demonstrate the transformative impact of strategic lighting investments.

Future Trends in Warehouse Lighting

Smart Lighting Systems

The integration of smart lighting systems with advanced sensors and controls enables dynamic adjustment of illumination levels based on occupancy, daylight levels, and operational requirements. Smart lighting solutions offer enhanced flexibility, energy savings, and data-driven insights into warehouse operations.

Integration with IoT Technology

The convergence of lighting systems with Internet of Things (IoT) technology enables real-time monitoring, predictive maintenance, and seamless integration with other smart devices. IoT-enabled lighting platforms empower warehouse managers with actionable insights to optimize energy usage and enhance operational efficiency.

Conclusion

In conclusion, lighting requirements for warehouses encompass a multitude of factors ranging from energy efficiency and maintenance to safety and productivity. By embracing innovative lighting technologies, adopting strategic design principles, and prioritizing employee well-being, warehouses can achieve optimal lighting solutions that drive efficiency, safety, and cost savings.

FAQs

-

How does warehouse lighting impact productivity?

Warehouse lighting directly influences productivity by improving visibility, reducing errors, and enhancing employee morale and well-being. -

What are the safety implications of inadequate lighting in warehouses?

Inadequate lighting increases the risk of accidents, injuries, and workplace incidents due to reduced visibility and compromised safety measures. -

How can energy-efficient lighting solutions benefit warehouse operations?

Energy-efficient lighting solutions offer cost savings, reduced environmental impact, and enhanced operational efficiency through lower electricity consumption and maintenance requirements. -

What role does lighting design play in optimizing warehouse environments?

Lighting design influences visibility, comfort, and safety within warehouse facilities, ensuring proper illumination of work areas while minimizing glare and shadows. -

Are there any government regulations regarding warehouse lighting standards?

Yes, government regulations establish minimum lighting requirements for workplaces, including warehouses, to ensure adequate illumination levels for safety and productivity.